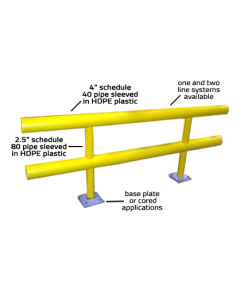

Standard Guardrail

Our Standard Guardrail is made from schedule 40 and schedule 80 steel pipe, which is sleeved in HDPE plastic to make the guardrail maintenance-free and paint-free. Customization is available as the guardrail can be made in both one-line and two-line options, both of which have the strength to stop a 12,000-pound forklift in its tracks. The guardrail is also easy to install as there is no field welding needed and the guardrail is able to be installed upon arrival.

- Maintenance-free, with no need to paint

- Won’t rust or crack in any environment

- Maximizes valuable floor space with small deflection rate; can be placed within 6 inches of walls or equipment

- Easy installation; no field welding required

- Modular; can be moved and reused as floor plans change

- Customizable based on protection needs

- Significant reduction of repair and replacement costs

For more information on our Standard Guardrail or Heavy-Duty Guardrail option, please contact our sales team today.

Pipe post made of 4” schedule 40 pipe

Pipe rail made of 2½” schedule 80 pipe

Sleeved in UV and antistatic treated ¼” polyethylene thermoplastic Standard heights: 14 ¾”, 27”, 36”, 42” Standard lengths: 48”, 72”, 96”, 120” One- & two-line systems Custom configurations available Installation options: core-in, plate mount, or steel floor sleeve Ships fully assembled

©2024 J&P ATM Site Experts, LLC

©2024 J&P ATM Site Experts, LLC